How a Family Business Quietly Became the U.S. Leader in Microsurgery

Trusted by 500 institutions and 2,500 surgeons, AROSurgical shows what focus on quality and service can achieve.

An Interview with Fred Phelps, AROSurgical, President & Founder

By Guillaume Viallaneix | Editor-in-Chief, The MedTech Digest & President, MedTech Momentum

Some medtech companies chase scale and quick exits. Others, like AROSurgical, build for trust, longevity, and impact. Fred Phelps founded the company nearly four decades ago, and today it is relied on by 500 institutions, 2,500 surgeons, and has played a role in more than 50,000 surgeries worldwide. Beyond the U.S., AROSurgical has established a strong international presence in markets such as India, Canada, Scandinavia, France, and South Africa.

Fred, thank you for joining me in our Experts in Motion series and for sharing your remarkable journey with our readers. In this conversation, we’ll explore your early beginnings, how you built a family business that became a U.S. leader in microsurgery, the tough challenges you faced, and the lessons entrepreneurs can learn from your story. Readers will walk away with insights into building long-term partnerships, navigating regulation, protecting pricing in competitive markets, and most of all, the importance of quality and customer service in medtech.

Guillaume Viallaneix (GV): Fred, let’s start at the beginning. Where did you grow up, and what shaped you early on?

Fred Phelps (FP): I was born in Philadelphia, but I grew up out in the countryside. I worked on farms from a young age. It was tough work, but it taught me discipline, and that’s carried me through my whole life.

GV: And education? Did that play a big role in preparing you?

FP: Absolutely. I studied accounting and finance at Susquehanna University, then pursued graduate studies at Drexel. Later, I earned my CPA with Deloitte. That foundation in finance gave me the confidence to run a business later on.

GV: Going from accounting to MedTech seems like quite a leap. How did it happen?

FP: My first real break was with Air Shields, a company making incubators for premature babies. I started as an internal auditor, but the role took me around the world, to South Africa, London, and Tokyo. Eventually, I became president of Pilling, a company specializing in cardiovascular surgical instruments. That’s where I built key relationships with suppliers in Germany and Japan, partnerships that became the backbone of AROSurgical.

GV: So those relationships with suppliers weren’t just important early on. They became the cornerstone of your future company.

FP: Exactly. Trust is everything. Those manufacturers knew me, and I knew I could rely on them.

GV: And eventually, you felt ready to strike out on your own?

FP: Yes. By the mid-1980s, I felt it was time to take everything I’d learned about finance, global business, and surgical instruments, and create something of my own. I had trusted partners in Germany and Japan who believed in me, and I believed in the vision: bringing world-class instruments directly to U.S. surgeons. In 1986, I launched AROSurgical from my apartment in California with just a $10,000 line of credit. It was a leap of faith, but one I knew I was ready for.

GV: Starting out small, what was your strategy? How did you decide to build the company differently?

FP: I wanted to stay close to the surgeons. Rather than building out a big sales force or traditional distribution network, I chose to work directly with them. By the mid-1990s, we had even established one of the first medtech websites, where surgeons could order clamps and sutures directly from us online. That direct model gave us an edge, kept us lean, and built stronger relationships with the very people using our products.

GV: That’s such a forward-thinking move for the 1990s, cutting out middlemen and connecting directly with surgeons. That must have built incredible loyalty.

FP: It did. Surgeons knew exactly who they were dealing with, and they knew we’d deliver.

GV: Fred, you’ve mentioned your partners in Japan and Germany a few times. Why did you choose to work with those countries specifically?

FP: Simple answer: quality. I never get an imperfect product from Japan or Germany. If something isn’t perfect, they don’t ship it. In Japan, for example, the same precision that goes into Citizen and Seiko watches goes into making micro clamps and sutures. They’ve mastered miniaturization, and that’s why their products are unmatched. In Germany, it’s the same story. Their craftsmanship in surgical instruments is second to none. I’ve tried other sources over the years, and honestly, nothing compares. That’s why I’ve stuck with those partnerships for decades.

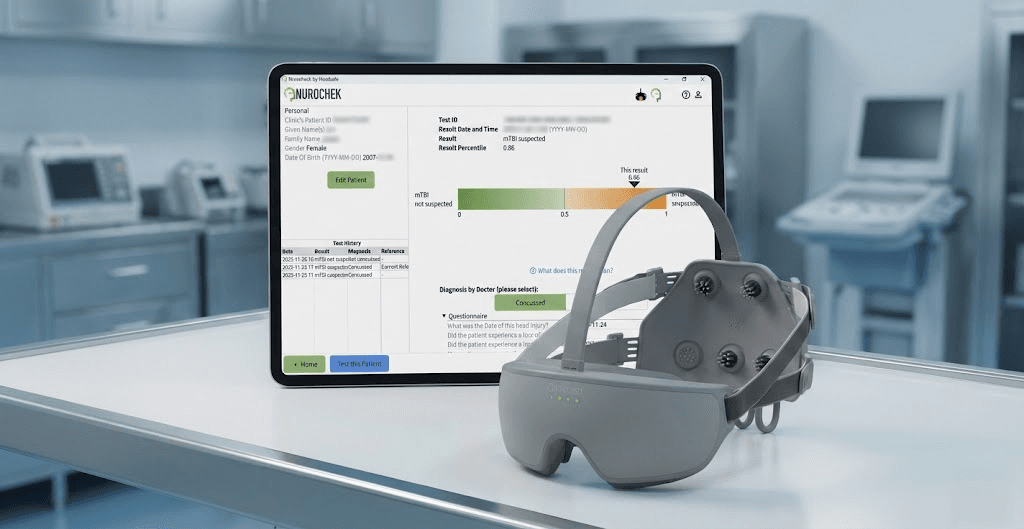

GV: Tell me about the products. What sets your clamps apart?

FP: They’re manufactured in Japan using hemispherical jaw technology. That means they grip vessels securely but gently, with minimal trauma. It’s precision you can trust.

GV: And these clamps have been used in some big moments, right?

FP: Yes. Back in 1999, our clamps were used in the world’s first successful hand transplant at the University of Louisville Jewish Hospital. Since then, they’ve played a role in breast reconstruction, liver transplants at the University of Pittsburgh, and many other life-changing surgeries. Over the years, more than 50,000 procedures worldwide have relied on them.

GV: That’s incredible. And the sutures?

FP: Our nylon microsutures go down to 11-0 and 12-0, so fine they’re invisible to the naked eye. The Japanese pioneered a laser-drilled needle attachment that eliminates tissue trauma. It’s so effective that even Ethicon adopted it later. Surgeons rely on them because they work every single time.

GV: Who are your customers today?

FP: We supply more than 500 institutions, places like Duke, New York Presbyterian, Emory, and the University of Chicago. Around 2,500 microsurgeons across the U.S. use our clamps and sutures.

GV: And why do they keep choosing you?

FP: Two words: quality and service. Our partners in Japan and Germany never send a bad product. And if a surgeon needs something urgently, we’ll move mountains to deliver it, even flying a clamp on a commercial flight if we have to. That’s how you earn trust for decades.

GV: Many medtech firms struggle to tell their story. How have you approached it?

FP: For me, it’s always been about direct communication with surgeons. But storytelling matters too. That’s where bringing on a trusted marketing partner, such as MedTech Momentum, helps share more than just specs. Those are the personal stories people remember.

GV: What’s next for you and AROSurgical?

FP: We’re expanding our suture business, looking into ophthalmic instruments, and continuing as a family business. Marketing will also play a much bigger role in our next chapter. For years, our focus was on direct surgeon communication, and that worked well. But as we look to the next decade, we know we need to amplify our story. That means highlighting the human impact of our technologies. Long term, I want AROSurgical to be remembered not just for our great products, but for the lives touched and transformed. That’s what makes it all worthwhile.

Fred Phelps’ journey with AROSurgical proves that when you combine cutting-edge technology with a true focus on people, you can build a company that lasts. Nearly 40 years on, his family business serves more than 500 institutions and 2,500 surgeons, with instruments trusted in over 50,000 surgeries worldwide.

For medtech entrepreneurs, the takeaways are clear: nurture supplier partnerships you can trust, stay lean and close to your customers, let service be your strongest differentiator, and tell your story with confidence. These are the principles that helped AROSurgical stand shoulder-to-shoulder with industry giants, and they can guide today’s innovators too.

From its Newport Beach headquarters, AROSurgical continues to deliver FDA-cleared and CE-marked instruments crafted in partnership with German and Japanese manufacturers. To explore the portfolio of microsurgical clamps and sutures, request samples, or connect directly with Fred Phelps and his team, visit www.arosurgical.com or email info@arosurgical.com.